DPA Helps Supplier Resolve Inventory and Return to Vendor Issues

A fast-growing supplier of tankless water heaters experienced a high rate of inventory errors. DPA supported the work of a kaizen team within the company to identify and solve process

Finished Goods Strategy

DPA’s Kaizen team helped a medical device manufacturer implement a finished goods strategy to reduce lead times and satisfy delivery commitments to its customers.

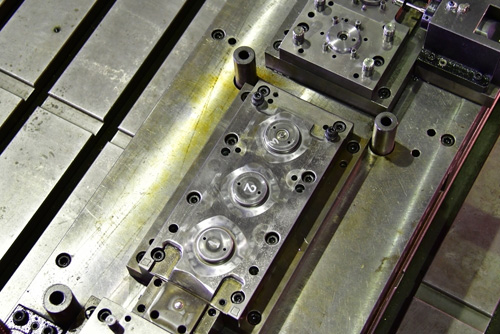

Adapting Two Production Cells

DPA led two Kaizen events with a New England-based manufacturer of complex metal stampings and surgical cutters to adapt production cells.

Increasing Productivity – Nutmeg Container

Daniel Penn Associates helped Nutmeg Container increase productivity with workflow layout and total productive maintenance (TPM) support

Clean Room Staple Loading Kaizen Event

A medical device manufacturer needed to increase its annual production without compromising safety or customer delivery schedules.

Three Kaizen Events Help Component Supplier Meet Delivery Expectations

As a result of the three Kaizen events DPA managed, the company was able to significantly improve their delivery performance while reducing lead times.

Re-thinking Product Flow, Parts Picking and Assembly Standards

How to increase efficiency by reducing time to prep and assemble parts.

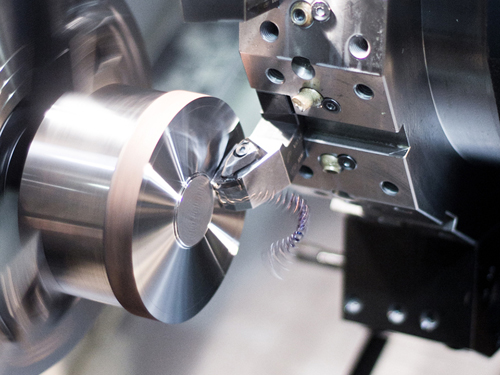

Slashing Set-up Time for a Global Manufacturer

DPA worked with a 5 member employee team in a Kaizen event to reduce the line’s changeover time from 5 hours to less than 2.5.