The path to operational excellence

The path to operational excellence

Improvement & Asset

Management

Stay GMP/cGMP Compliant

Industry Solutions

Daniel Penn Associates engages your people, processes and systems.

Financial Services

Improve your operations and staffing.

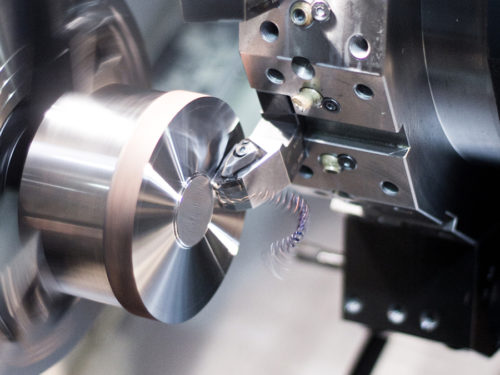

Manufacturing

Daniel Penn Associates helps durable goods, pharmaceutical,

Utilities

Enhance work management and prevent costly repairs.

Government

Guide your teams to own their process.

Hospitals and Healthcare

Support your environment of care.

Services

Nurture a culture and mindset of continuous improvement. We work with teams to streamline operations, reduce waste, boost productivity and enhance customer service.

Improve reliability centered maintenance and overall equipment effectiveness. We’ll customize your PM and OEE program with processes and systems to mitigate costly breakdowns and maximize uptime.

Solve receiving, storage, layout, shipping and distribution snafus. We recommend and help your company make end-to-end improvements that remove process roadblocks and meet customer requirements.

Take a fresh look at your facility’s compliance roadmap. Measure six crucial aspects of your process definitions and controls. Our assessment tool will help you address deficiencies, improve cGMP and GMP practices and pass your next inspection.

Anticipate and plan the labor required to meet workload demands. We develop staffing models that support growth, accommodate contingencies and respect budgets.

Don’t just talk about lean. Learn how to sustain it at all levels. From onsite leadership training and Yellow, Green and Black Belt certification programs to online courses, we provide a foundation for your organization’s lean continuous improvement activities.

Strengthen how your people collaborate. Enhance the quality of decisions and attainment of goals. We help you build a culture that fosters productivity, collaboration, accountability, and continuous learning.

Explore virtual or onsite training options designed to advance employee knowledge and support lean improvement efforts.

Daniel Penn Associates’ team member Mike Beauregard expertly facilitated our company’s Kaizen. He quickly identified readiness delays and process inefficiencies, aligning cross-functional teams to reduce schedule risk during peak demand. By fostering accountability while maintaining a highly collaborative environment and engaging frontline operators, he drove stronger adoption, clearer expectations, and lasting standardized work practices.

Len Tartamella

Manufacturing Engineering Supervisor, TIGHITCO

We completed a Lean Audit and Kaizen project with Daniel Penn associates in August of 2020. Our facilitator, Kate McGovern, made sure we understood our schedule, was flexible with dates, and helped us complete the task in a remote environment. We found the course work to be well thought out and the examples to pertained to our work environment. We were able to complete a Kaizen that will lead to valuable time savings for both our staff and our customers.

Gail Thomas

Deputy Division Director, Division of Medical Services, Department of Social Services

Each event Daniel Penn has facilitated at our plant results not only in real and measurable improvements in quality and cost but also a fertile educational experience. The environment Daniel Penn consultants create during these team events is filled with positive reinforcement that fully engages every team member.

Kenneth Lisk

President, NN Inc. Life Sciences Division

Through their implementation of a maintenance excellence program at New York-Presbyterian Hospital and in close collaboration with its facilities staff, the DPA team paved the way to a zero-violation finding within the hospital’s facilities operations by the Joint Commission.

William J. Tortoriello

Former Director of Facilities Operations, New York Presbyterian Hospital

The Daniel Penn team was well organized, translated my expectations at a very high level, and ultimately delivered a stellar end product. They not only kept our team updated almost daily on progress but in their interactions at the various staff levels, proved they truly had the knowledge and people skills to "mine" the necessary data with minimal inconvenience to us. I'd gladly work with them again on any project, it was truly a pleasure and an extremely positive experience for my team.

Dean Petruzzi

Former VP of Operations, Cambridge Housing Authority

I have had Daniel Penn come into our business multiple times to work on tough complex system problems. Every time we have done this, the process/area we focused on turns from a problem to one of our best running processes.

Kathleen Daudish

Vice President, Engineering and Operations, Eemax – a Division of Rheem Manufacturing

Want to learn more?

We’ll help you implement solutions that improve supply chain performance, reduce costs, and enhance revenue opportunities.

(860) 232-8577

Email

Get Lean. Reduce Costs. Optimize the Supply Chain.

40+

Years of Experience

400+

Happy Clients

100%

Satisfaction

News and Resources

Build strategies, build confidence, build your business.