Root Cause Analysis and The Five Whys help cable manufacturer regain control of production cell

Daniel Penn Associates helped a precision cable manufacturer reduce lost runs by 83%.

Fiber materials producer gets to the bottom of waste-causing issues

Daniel Penn Associates helped a fiber-based product producer meet its waste reduction targets through data review, root cause analysis, and action steps.

Preventive and Predictive Maintenance for a Pharmaceutical Manufacturer

A case study on manufacturing focusing on preventive and predictive maintenance planning and scheduling for a pharmaceutical manufacturer.

How DPA Helped a Hospital’s Engineering Department Set Its Maintenance Staffing Requirements

Helping a large medical school-affiliated hospital reassess maintenance staffing requirements for its engineering department’s shops.

The Kaizen Multiplier Effect

Team-Led Improvement Ideas Boost Safety, Efficiency, and Uptime for Precision Molding Operation CompanyA global precision manufacturer of specialty pumps for personal care products. ObjectiveConduct a process mapping to find ways to improve

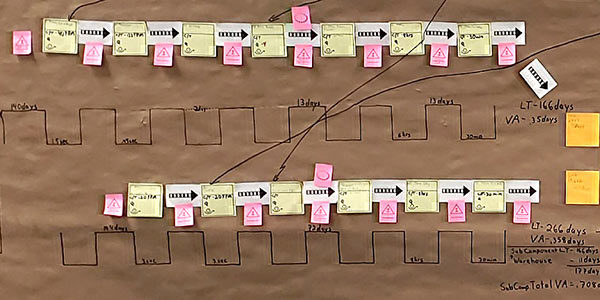

Value Stream Mapping Helps Cable Manufacturer Meet Customer Requirements

Daniel Penn leads value stream mapping (VSM) and lean continuous improvement Kaizen event to increase efficiency and lead times.

A Manufacturer of Commercial Explosives Dramatically Reduces Die Changeover, Startup and Shutdown Times

A leading manufacturer of commercial explosives worked with the DPA team to reduce die changeover time for production of the company’s shock tube lines.

How One Pharma Facility’s FDA Compliance Efforts Succeeded in Maintenance Reliability

We recently worked with a pharma client using DPA’s six-factor assessment tool. The client had received an FDA 483 Inspectional Observations report, detailing several conditions and findings that put the

Slashing Set-up Time

A global manufacturer of aircraft and gas turbine components retained DPA to conduct a Kaizen event that would reduce the 18 hours required for the set-up of a key machine.