How One Pharma Facility’s FDA Compliance Efforts Succeeded in Maintenance Reliability

We recently worked with a pharma client using DPA’s six-factor assessment tool. The client had received an FDA 483 Inspectional Observations report, detailing several conditions and findings that put the

Baseball and Operational Excellence

“Baseball is a simple game. You throw the ball. You catch the ball. You field the ball.” – Durham Bulls coach Larry Hockett, from the movie Bull Durham.

Slashing Set-up Time

A global manufacturer of aircraft and gas turbine components retained DPA to conduct a Kaizen event that would reduce the 18 hours required for the set-up of a key machine.

An Operational Nod to Anthony Bourdain

Sometimes operational lessons get reinforced by unexpected players. This one begins with a story surrounding the late great Anthony Bourdain.

DPA Helps Sealing Products Producer Reduce Lead Manufacturing Lead Time By 64.8%

DPA helps sealing products producer reduce lead manufacturing lead time by 64.8% applying sound Value Stream Map (VSM) and other lean principles.

A New Look at In-sourcing and Cell Layout Boosts this Manufacturer’s Capacity by 107%

Identifying risks to product quality and other supply chain issues of logistics and costs reduces lead times by 60%, cell layout boosts capacity by 107%.

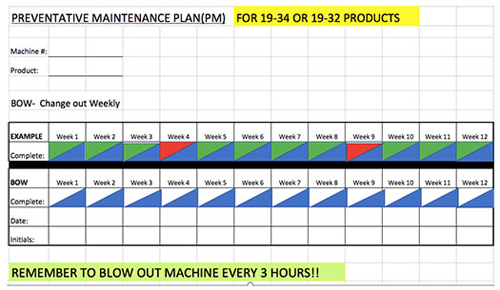

Helping a Specialty Materials Producer Apply FMEA And Preventative Maintenance To Reduce Scrap

The Kaizen team worked with DPA to identify simple, repeatable methods for capturing the amount of scrap generated at the process.

Helping a Specialty Materials Producer Embrace PDCA Culture

DPA recently worked with a manufacturer of wire, cables and connectivity products to reduce scrap at one of their factories.

How to get OCM Right: Questions and Steps to Lasting Change

Is your business contemplating operational change? Most organizational change programs fail is they don’t take thoughts and emotions into account.