DPA Helps Sealing Products Producer Reduce Lead Manufacturing Lead Time By 64.8%

DPA helps sealing products producer reduce lead manufacturing lead time by 64.8% applying sound Value Stream Map (VSM) and other lean principles.

Reducing setup times, increasing safety and multiplying output

A manufacturer of components for medical device, commercial and bearing needs to reduce work-in-process bottlenecks and increase production.

A New Look at In-sourcing and Cell Layout Boosts this Manufacturer’s Capacity by 107%

Identifying risks to product quality and other supply chain issues of logistics and costs reduces lead times by 60%, cell layout boosts capacity by 107%.

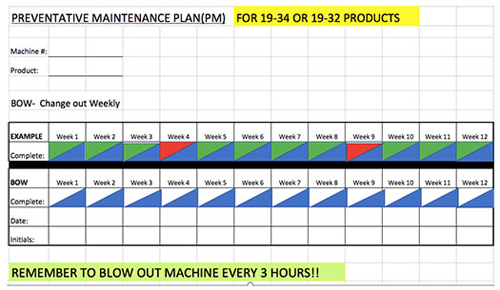

Helping a Specialty Materials Producer Apply FMEA And Preventative Maintenance To Reduce Scrap

The Kaizen team worked with DPA to identify simple, repeatable methods for capturing the amount of scrap generated at the process.

Helping a Specialty Materials Producer Embrace PDCA Culture

DPA recently worked with a manufacturer of wire, cables and connectivity products to reduce scrap at one of their factories.

Standardizing Set Ups and Reducing Re-work for a Fiber Products Manufacturer

Improving throughput was the challenge to find ways of standardizing setups while streamlining an increase in reliability on a major production line.

Production to Shipping Performance

How DPA helped improve the flow in the shipping department so that available goods are processed more efficiently increasing productivity in the shipping department by 30%.

DPA Helps Aerospace Supplier Ensure Machine Reliability

A manufacturer of specialty components wanted to make sure that its molding press equipment will reliably produce a 60% increase in orders from its biggest aviation customer.

Implementing a Pull System on a Medical Device Production Floor

DPA performed a Kaizen event to implement the pull system for the Die Stamp value stream on a medical device production floor.