Learn from the present, build for the future: What’s your warehouse and supply chain strategy?

For good or bad, our COVID-19 crisis shows the global impact of supply chain and warehouse protocols.

How to immunize your supply chain from global crises

U.S. supply chain experts are weighing in on what can be done to make our supply chain more resilient now and after the COVID-19 pandemic abates. How will your company adapt its supply chain to respond to future global shocks?

Streamline your delivery systems

A high technology manufacturing facility in Mexico was not meeting customer delivery dates. Daniel Penn Associates assessed their warehousing and logistics operations. As a result, we implemented improvements to satisfy customer delivery requirements.

The project addressed multiple issues: materials management, purchasing, receiving and receiving inspection, stock locating, inter-plant transfers, transportation, manpower loading, supplier integration, inventory replenishment, and reorganization.

To meet the client’s objectives, we implemented corrective actions including:

- Redesigning the receiving and inspection process

- Developing a staffing matrix for warehousing operations based on workload and performance standards

- Consolidating three warehouse operations into one

- Establishing transportation runs and frequency between plant and warehousing operations

- Establishing materials and purchasing replenishment processes

- Implementing accurate inventory transaction and tracking solutions

- Redesigning the materials flow process between warehousing operations in the US and Mexico

- Designing and implementing a warehousing management reporting system for tracking performance and conducting root causes analysis

How-To’s and Success Stories

- Out of Space? Maybe Not!

- A Warehouse and Logistics Plan to Keep Pace with Growth

- Optimizing the Pick Area for Shipping Operations

How We Work

Daniel Penn Associates can tackle and solve your receiving, storage, layout, shipping and distribution issues. We get to the bottom of your door-to-storage, storage-to picking, and picking-to-shipping woes.

Our process involves talking to employees who do the receiving, storing, picking and shipping. Examining how staff levels and picking tactics can support shipping requirements. Evaluating how space and cube storage systems affect warehouse layout. Learning how packing and shipping materials are used and disposed of. Evaluating equipment and product placement, process flow and congestion.

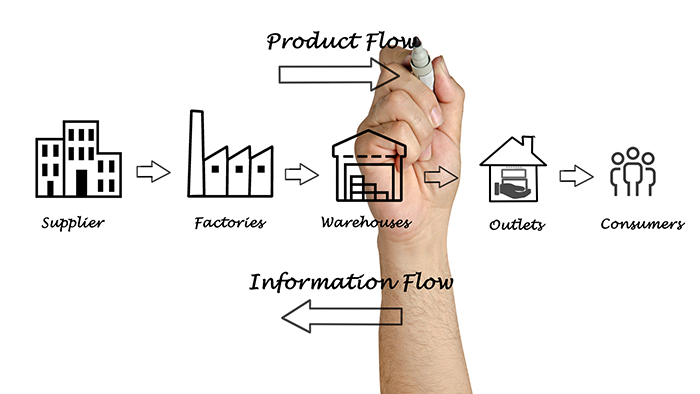

Based on our evaluation of your supply chain, warehousing and delivery systems end-to-end, we’ll recommend and help you implement improvements that support your vendors, employees, distributors, and customers.