Components manufacturer streamlines the movement of parts, reduces idle time by more than 50%

By Michael Beauregard, Senior Consultant

The Problem

A manufacturer of precision-machined aerospace parts faced a 15% drop in efficiency compared to the previous two years. Delays in the Deburring, Blasting, Wash, Chemical Clean, and Part-Marking support processes created major bottlenecks. Consequently, these issues led to significant idle labor time, part buildup between stages, and excessive movement across the floor. The company calculated that it lost nearly 1,000 labor hours due to these inefficiencies.

Objectives

The company set clear goals: reduce idle time in the deburring area (the main source of delays) by 50% and boost overall productivity by 25%. To achieve this, they committed to documenting and implementing a new workflow, training employees, enhancing safety, and applying visual factory techniques to improve 5S, communication, and accountability.

Under the guidance of Daniel Penn Associates Senior Consultant Mike Beauregard, the team closely observed the current production floor—a crucial first step in continuous improvement. During this assessment, they identified several critical issues:

- Associates dropped off and picked up products based on floor space and availability, following inconsistent directions from colleagues and managers.

- The lack of defined incoming/outgoing areas or FIFO lines created confusion.

- Workers found it difficult to visually determine which tasks were complete.

- Boxes and crates sat too close to active workstations, creating safety hazards.

- Cluttered spaces blocked egress routes.

- Boxes, hoses, and pallets caused frequent trip hazards.

- The chemical clean process delayed production because it was located outside the natural workflow.

Rethinking Workflows

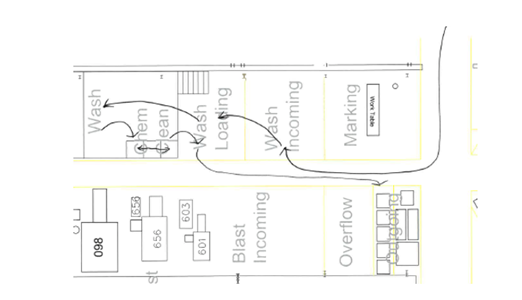

To address these challenges, the team tested and measured travel time across different scenarios. Then, they designed new workflows for the Deburr, Wash, Chemical Clean, and Part-Marking processes. They relocated key equipment to streamline part flow and reduce unnecessary movement.

Before and After Workflow Comparisons

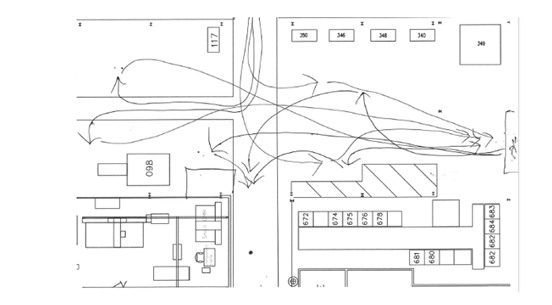

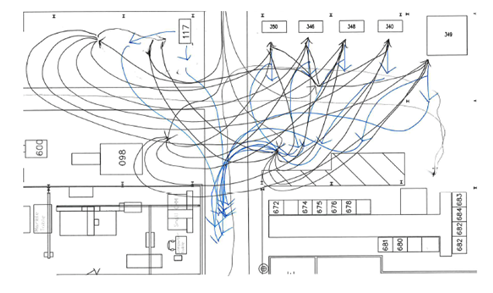

Original Workflow for Deburr

New Workflow for Deburr

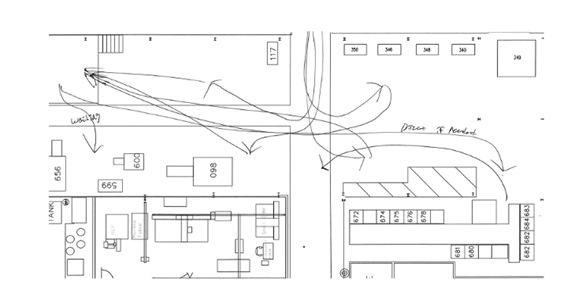

Original Workflow for Chemical Clean

New Workflow for Chemical Clean

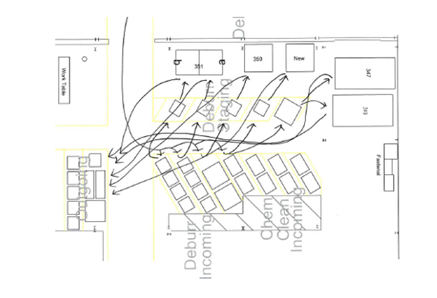

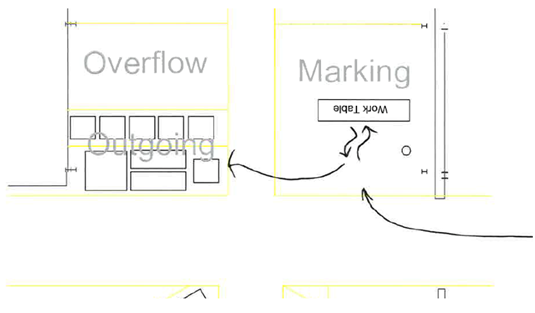

Original Workflow for Part-Marking

New Workflow for Part-Marking

Travel Distance Saved

| Area | Original | Improved | Yearly Savings |

|---|---|---|---|

| Deburr | 170 ft. | 115 ft. | 153,262 ft. |

| Wash | 175 ft. | 150 ft. | 62,602 ft. |

| Blast | 265 ft. | 140 ft. | 35,052 ft. |

| Part Making | 270 ft. | 50 ft. | 331,558 ft. |

| Chemical Clean | 370 ft. | 150 ft. | 62,150 ft. |

| Alodine | 260 ft. | 170 ft. | 78,812 ft. |

Results

By reconfiguring workflows in these support processes, the team eliminated nearly 740,000 feet of annual travel distance for moving parts. This improvement reduced idle time by 38% on a weighted average. Once all planned changes are implemented, the team expects to exceed its goal of reducing idle time by more than 50%.

Additionally, the company will save another 220,000 feet of travel while reworking parts in Deburr. The team also recommended upgrading lighting in the Deburr area to match the inspection area, reducing rework caused by poor visibility. Furthermore, consolidating Part Marking operations will save operators time by eliminating unnecessary trips to marking machines.

In the Wash process, productivity improvements will save about 125 labor hours annually.

Benefits

The new workflows transformed daily operations. Deburr operators now know exactly where to find their next job. There is no more wasted time searching for parts. Each part moves directly to its designated area, and operators make just one move to reach the next job pallet.

Moreover, for two-thirds of all parts, there is no movement between the Wash and Chemical Clean processes. This eliminates WIP buildup, multiple pallet handling, and hoist waiting time.

Safety Improvements

Safety also improved significantly. The deburring process now operates in an airflow-controlled environment separated from the open floor. Backdraft booths provide better ventilation for large parts, and the eye wash station now sits in a more accessible location.

Improved organization has eliminated unsafe conditions, such as people walking on pallets or encountering obstacles behind work areas. Each booth now has defined spacing, blast dust collectors are properly positioned, and dust hoppers are easy to reach for daily maintenance. Operators can now use parts washer controls without bending, reducing ergonomic strain.

Lessons Learned

After the kaizen event, team members reflected on their experience. They had re-mapped workflows, itemized and budgeted for new equipment, and documented follow-up actions. They strongly supported the implementation of visual factory organization, which allows anyone entering the area to immediately see part locations and workflow status.

Team members were surprised by the travel distances required in the original setup and proud of their role in improving efficiency. This kaizen event not only enhanced workflow but also empowered employees to continuously seek new ways to improve their processes.

If you were interested in this article, you may be interested in:

- How to Tackle Overall Equipment Effectiveness

- Kaizen Team Boosts Packaging Operation OEE by 66.5%

- Value Stream Mapping Helps Cable Manufacturer Meet Customer Requirements