Part II: Set-up Reduction for the Bindery Inserting Machines

Printing Teams Boost Output and Cut Waste with Set-Up Reduction Event

A national printing and direct marketing company hired Daniel Penn Associates (DPA) to help employees lead two Kaizen events focused on set-up reduction. These events aimed to cut set-up times, speed changeovers, and improve overall equipment effectiveness (OEE) for insertion and bindery operations.

After reducing a bindery machine’s set-up time by 63%, DPA supported another Kaizen event at the same plant. This time, the team focused on 12 high-speed inserting machines that produced 347 million pieces in one year. Each machine averaged 160 changeovers, each lasting about an hour. Cutting set-up time could add 1.28 million more pieces annually. The company also wanted to reduce scrap from 8% to 2%, gaining another 307,000 pieces per year.

Inserting Machine Findings

The team studied one inserter as a pilot and used the findings for all 12 machines. Video of the pilot changeover showed a 53-minute setup. Procedures, checks, and adjustments varied across three shifts. Because the operator wasn’t part of the setup, the mechanic had to feed the machine alone. The mechanic slowly ramped up speed instead of reaching the target rate quickly. Workers also wasted time walking back and forth during setup.

Identifying Solutions

The team found 67 improvement opportunities. They chose key ideas, created a new setup procedure, and retrained all inserter staff. Now, the operator joins the mechanic during setup. The mechanic arrives before the line shuts down. A red-yellow signal warns the team before changeovers. Workers bring setup boxes on carts to reduce walking. Material handlers stage materials for upcoming jobs.

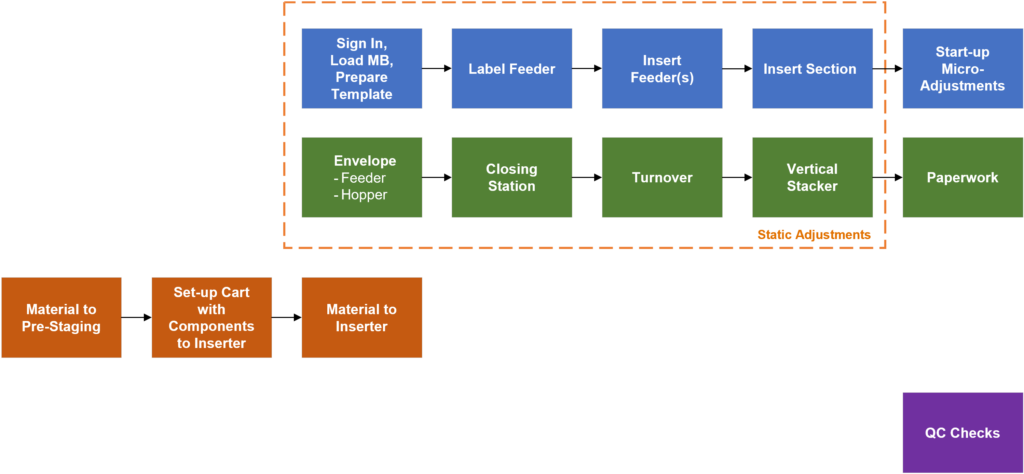

Inserting Machine – Revised Process

Inserting Machine Results

After 90 days, the team had implemented most of the 72 improvement ideas. Operators, mechanics, and supervisors now communicate more effectively. The new setup takes 20 minutes—a 62% time savings. Scrap dropped from 8% to under 1%. The improved setup lets the company produce 12 million more pieces annually per machine. With 16 setups each month and a rate of 13,000 pieces per hour, the 12 inserters can now produce 972,000 more pieces monthly—26% higher than the original estimate. The team is applying these improvements and training to the remaining machines. Supervisors and shop floor staff plan to expand the process to all shifts.

Lessons for Continuous Improvement

Employees learned lasting lessons from these setup reduction events. They now identify good and bad product quality, recognize and remove waste, and eliminate unnecessary movement. Teams create and sustain standard work and maintain proper tools. Most importantly, employees have strengthened communication and coordination across departments.

If you were interested in this article, you may be interested in:

- Components manufacturer streamlines the movement of parts, reducing idle time by more than 50%

- How to Tackle Overall Equipment Effectiveness

- Kaizen team boosts packaging operation OEE by 66.5%

- Value Stream Mapping Helps Cable Manufacturer Meet Customer Requirements

- Manufacturer of Commercial Explosives Dramatically Reduces Die Changeover, Startup, and Shutdown Times

Ready to discuss your operational goals and challenges? We’re ready to listen. Give us a call at (860) 232-8577.