Part II: Set-up Reduction for the Bindery Inserting Machines

Printing operation employees dramatically boost output and reduce scrap with set-up reduction events that improve flow, standardize work, and slash waste.

Apply a Lean Lens to Your Production Challenges

Discover how a fast-growing manufacturer used Lean manufacturing and Kaizen events to improve processes, boost productivity, and align employees for sustainable success.

Boosting Productivity Through Bindery Machine Setup Reduction

Printing operation employees dramatically boost output and reduce scrap with set-up reduction events that improve flow, standardize work, and slash waste.

What it Really Takes to Control Inventory

Inventory control plays a critical role in manufacturing facilities. Proper spare parts management can reduce downtime, and increase profit margins.

Change Management Needs to Change

Why employees really reject change? DPA consultant Peter Harlamon shares strategies and tactics from his involvement in challenging labor-management negotiations.

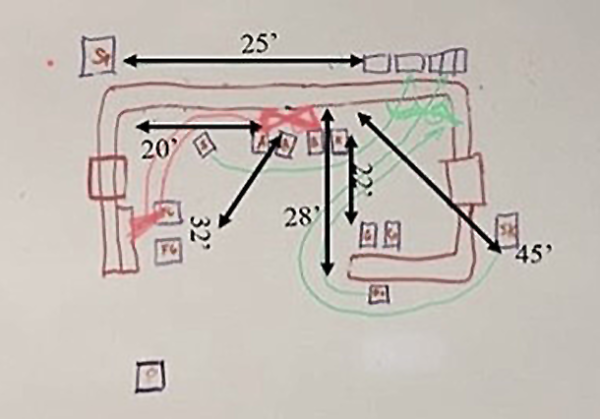

Changeover improvements help company boost machine output and reduce waste

More than 200 hours per year of downtime from the company’s machines were compromising on-time deliveries to customers. Read how this company was able to improve output and reduce waste.

How standard work, eliminating waste, and communication are helping this producer improve on-time shipments

How standard work, eliminating waste, and communication are helping this producer improve on-time shipments.

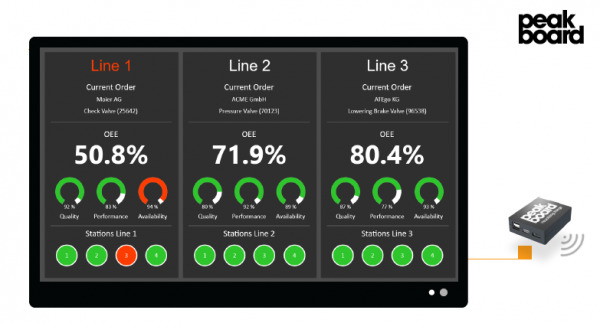

Kaizen team boosts packaging operation OEE by 66.5%

How an international manufacturer of materials for construction applications was able to improve operational excellence by 66.5%.

How to Tackle Overall Equipment Effectiveness

Original equipment effectiveness (OEE) is the product of availability, performance and quality. Knowing how to use these elements can help manufacturers improve operations.